Choosing The Right Soft Serve Machine

The right machine makes all the difference. Use this guide to ensure you get the knowledge you need to set up your profitable (and delicious!) soft serve or frozen yogurt business.

4 Things to Consider Prior to Purchase

1

Serving Size and Output

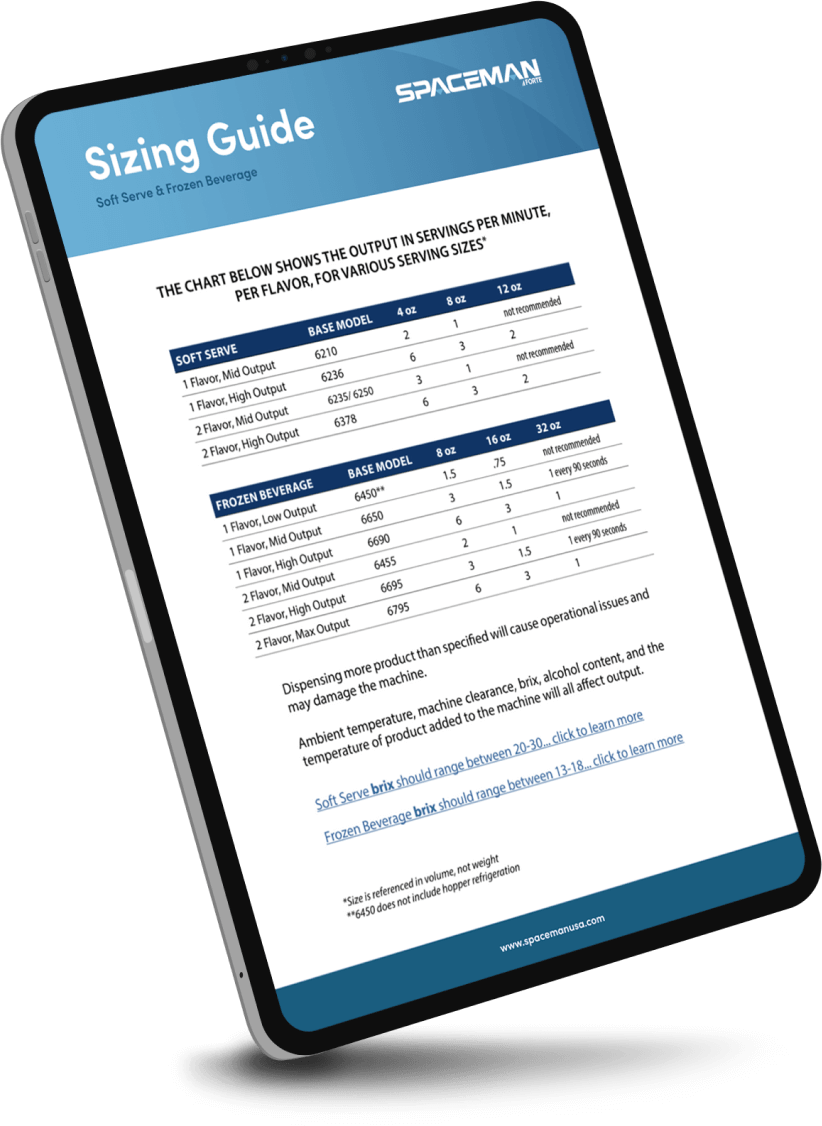

One or two flavor models are standard. Two flavor machines have three handles, the middle being a twist option and are referred to as twin twist machines.

2

What serving size? How many servings per minute and hour?

⚠️ this is the most important consideration to get right.

Depending on your serving size and output, you can choose an ideal freezing cylinder size and rated output. Note that serving sizes are generally a measure of volume, not weight. This will make more sense as you learn about overrun and how air is added to the product thereby increasing the product volume.

It is important to think of serving size in volume because the freezing cylinder (where frozen product is kept ready to dispense) is specified in volume, or how much frozen product it can hold. As you dispense frozen product from the freezing cylinder, new liquid product will come in from the hopper (also specified in volume).

If one pulls too fast for the size machine then the product will either be liquid or it will starve the cylinder.

If you are serving small sizes (3-5 ounces) and a low quantity of them per minute or hour, then you can stay in a lower capacity machine with a smaller freezing cylinder (less product available at any given time).

Purchasing a machine with a higher capacity than you need can result in wasted product, high energy costs, and higher upfront costs. On the flip side, having a machine with too low of a capacity or rated output will mean lost sales and frustration.

If you attempt to serve more than the machine is designed to produce, then you will starve the freezing cylinder or have poor quality product. Starving the machine leads to freeze ups and headaches you do not want. There is no way to make a low capacity machine preform to a higher output, it is similar to ice machines, which can only product up to a certain amount of ice per hour.

Never more. If you know how many servings you intend to do per hour and what size, we can make sure you get the right machine for your application. So we ask “How many servings during your busiest hour?”

Some cafeterias will serve 90% of their sales during a one hour lunch period. Basing your buying decision on this information is much more conducive then basing it on daily servings. We recommend to take it a step further, “How many servings per minute”. That way, if you absolutely need to have a certain number of servings in one minute we can size the machine accordingly.

Below are links to size charts for single flavor and two flavor (twin twist) soft serve machines.

SOFT SERVE SIZE GUIDE

Note: A typical soft serve swirl may have a diameter of two inches. As a rough estimate a two inch diameter swirl that is three inches tall will be a 5 oz. serving. A four inch height will be a 7 oz. serving, and so on, each inch of height will add approx. two ounces of volume (provided the diameter remains at roughly two inches).

If you increase the diameter of the swirl then the volume per inch of height goes up quickly. For example a three inch diameter swirl that is three inches tall will be an 11 oz. serving. This is a more common diameter for product which is being served in a cup or bowl as opposed to a cone. Therefor a larger cylinder and higher output machine would be recommended.

If you are interested in the math, as a rough guide you can follow the steps below:

- Find volume of cylinder

- Convert volume in cubic inches to fluid ounces.

- Rough formula is to divide the volume by 1.805 (meaning there is roughly 1 fluid ounce in 1.805 cubic inches)

3

Which type of product will you serve?

Frozen yogurt is traditionally sold by weight, so a gravity fed machine is your best option. Gravity fed machines allow a combination of product and air to flow from the hopper (refrigerated chamber for product storage) into the freezing cylinder (where the product is frozen into soft serve) by the force of gravity alone.

Typically, soft serve produced in a gravity fed unit will yield product that has 25-35% overrun. Overrun is the percentage increase in volume of product that comes out of the machine as soft serve due to added air. Ice cream is traditionally sold by large chains and quick serve restaurants through a pressurized or air pump machine, though chains like Checkers and Chick-fil-a use gravity fed machines – likely to keep operational experience at a minimum or for their preference of a denser, richer product.

Air pump machines can pull a higher, controlled percentage of air into the product before it enters the freezing cylinder. This means a higher overrun, typically 35-65% or more, depending on the ingredients in your product. Higher overrun results in a product that is lighter, airier, and typically regarded as creamier. It also means that your profit margin will increase if you are serving by volume or size, rather than by weight. This is because you are serving more air, and less product, per serving. Air pump machines are ideal for anyone who is interested in serving cones, especially if you plan to dip the cone. Custard, gelato, or sorbet will work in either an air pump or gravity machine and is a matter of preference or product manufacturer recommendation, though they are more often served through a gravity machine.

Depending on the manufacturer and model of your soft serve machine, changing flavors may be easy or difficult. If you plan to change flavors often, you should choose a machine with a digital viscosity control on the front of the unit, which is easy to adjust.

Viscosity is a loosely used term to describe the hardness, or consistency of the product. Most manufacturers will measure viscosity by the amps drawn from the motor (the amount of energy needed to turn the product), or by temperature, or a combination of the two.

4

Other features to consider

Hopper Agitator (H) periodically mixes the product that is being stored in the refrigerated hopper to keep product evenly cooled, mixed, and reduces ice buildup around hopper walls. Most Spaceman machines come standard with a hopper agitator.

Air Pump (A) or Pressurized soft serve machines use a pump and pressure to add a higher, controlled percentage of air to the product mix and maintain pressure in the freezing cylinder so that the air does not escape.

Air Cooled vs Water Cooled are the two methods for removing heat from the machine. Air cooled machines remove heat through a condenser fan, and water cooled machines remove heat through a liquid heat pump/plate. Water cooled machines are more expensive and in most states require a glycol or chiller system, since it is often illegal to use city water. A glycol system can be expensive, and the installation is an additional cost. Spaceman air-cooled machines have patented evaporator technology which means they reduce the heat output by 20-35% over other leading brands. Please take your time to consider choosing the right soft serve machine for your application, it will pay off in the long run!